Koh Young Technology, the leading supplier in the SMT inspection market, now offers a total 3D inspection and process optimization solution. It has been developed after more than 14 years’ experience, along with extensive knowledge gained by working with industry leaders around the world.

Not terribly long ago, Koh Young Technology began considering 3D imaging as the vital and indispensable specification in selecting our inspection systems. For many years the company has relied on their skills and experience to control the process and maintain high quality, even in light of the shortcomings of inspection tools. These shortcomings had occasionally created more problems than providing solutions. The discussion has now progressed beyond process control and defect detection to such issues as industry 4.0 and big data analysis for process optimization. All the while, the company has always had 3D measurement and inspection systems in mind as the indispensable assistant, providing reliable information that they can utilize.

Koh Young Technology, known as the leading 3D SPI (Solder Paste Inspection) systems provider for SMT, has a relatively short yet impressive history. The KY-3030 series that was introduced to the market in 2004 was a game changer in terms of accuracy and repeatability when it was introduced. It was (and is) also easy to use and program, featuring fully functional SPC software. It offered a whole new concept of utilizing the Solder Paste Inspection system as a process optimization tool instead of merely a defect finder; it was a new approach, where process experts could finally realize what they had intended to achieve. It simply had not been offered by any other OEM in the inspection industry, although there had been high expectations.

The way is the goal

Behind the scenes in this new company were ten engineers led by Dr. Kwangill Koh. Surprisingly, none of the members of this team of engineers were experts in optics; most of them were mechatronics experts who had experience in developing SMD mounters. Dr. Koh took an innovative approach, however. As the inventor of the world first high-speed gantry type mounters at his previous work in Mirae, he and his team of engineers began developing a 3D inspection system, the starting point being to eliminate the ambiguity of template matching as an inspection approach. They wanted to provide customers with reliable measurement values, which they could utilize, to understand and control printing process quality better. Dr. Koh applied his strong philosophy regarding making decisions for any new business or application, that his team must be the first one in the marketplace; else the company should has a game-changing solution that can change or stimulate the market. Since the goal is high, one does not fear taking on challenges to solve the most difficult problems. Koh Young Technology still adheres to his motto.

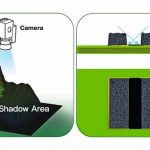

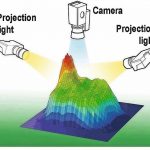

Dr. Koh and his team developed and engineered the best solution to overcome the common inspection bottlenecks at the time, including shadowing problems, when inspecting irregularly-shaped solder paste deposits. Later, Koh Young Technology developed their innovative Multi-Projection Phase Shift Moiré technology further to invent the world’s first 3D AOI (Automated Optical Inspection) system, capable of inspecting everything on an assembled PCB.

Growth, then leadership, from innovation

After its introduction in 2004, Koh Young’s KY-3030 series SPI quickly gained significant attention from top electronics manufacturers for its unique concept of process optimization based on highly accurate 3D measurement. In 2006, Koh Young Technology was reported to have the No.1 global market share in the SPI (after printing) market, with 20.7 % market share. The company’s share in 2015 was close to 50 % in the global Solder Paste Inspectionmarket, with more than 1,750 industry leaders and 9,000 systems installed worldwide. Koh Young has introduced a number of award-winning SPI systems with advanced capabilities and solutions including the aSPIre and KY8030 series, and an automated tabletop system.

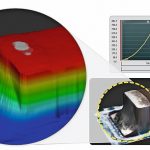

A major innovation that the company brought to the market was the Zenith 3D AOI system. This revolutionary system completely changed the mindset of the 25-year-old AOI industry. For a long time it had been common consensus that one had to spend a significant amount of time programming and tuning when running new product. One also needed to be a true expert in illumination and process parameters in order to find the optimal set of conditions to inspect each component type, even when dealing with new components that are added every day. By having parametric approach, Zenith made using AOI system as simple as learning one’s ABCs. Lifted leads can be detected now by measuring lead height, missing components are easy to detect since the system knows component dimension and height; and the solder joint profile is also measured using standard top-view optics.

Furthermore, the company has taken steps to support the industry 4.0 production environment goal. Its vision to connect all process-related information gathered from their inspection systems (3D Solder Paste Inspection, pre-reflow 3D AOI, post-reflow 3D AOI) is in line with the ongoing dream of the industry, i.e., fully automated production lines. Working with peer groups and customers with similar vision, Koh Young is drawing closer to providing the total process optimization solution with full traceability to defects and their root causes. Enabling tools include process dashboards to visualize the current status of all production lines, a centralized measurement value database, on top of the full line of 3D measurement-based inspection systems.

Work better, work smart

With the introduction of the Koh Young ‘Ksmart Solution’, the company is also taking the next step by expanding its R&D centers worldwide. This will bring the company’s electronics manufacturing know-how and process technology to the next higher level by incorporating advanced artificial intelligence. Koh Young has partnered with Binghamton University’s (SUNY at Binghamton) Integrated Electronics Engineering Center (IEEC) which has recently opened a new Smart Electronics Manufacturing Laboratory. In making the announcement, Seungbae Park, Director of the IEEC, said, “The ultimate outcome is the development of new electronics manufacturing schemes with the highest levels of efficiency and reliability.”

The company has also opened an Artificial Intelligence (AI) Center in San Diego, California, as recently as this past July. The center’s mission is to build a foundation of AI platforms for manufacturing process optimization. In South Korea, the KAIST R&D Center closely collaborates with Koh Young Technology’s Ksmart solution division to research and develop AI solutions utilizing machine learning and deep learning.

electronica, booth # A1-358

Well done is better than well said Benjamin Franklin

Share: