DfR Solutions, leader in quality, reliability, and durability (QRD) solutions for the electronics industry, announced the next release of Sherlock Automated Design Analysis software – Version 5.3. with a thermal-mechanical analysis. This provides the ability to capture system-level effects on solder joint reliability during temperature cycling. These effects include mirroring, over-constrained boards, and potting/coating.

Thermal issues are at the root of many product failures in today’s electronics designs. Modern products are more complex, smaller, require more power, and operate in more extreme environments than ever before. The more complex the design, the greater the thermal strain on the components. To help reduce this risk and ensure more reliable products, electronics manufacturers conduct time consuming and costly thermal-mechanical analyses on their devices.

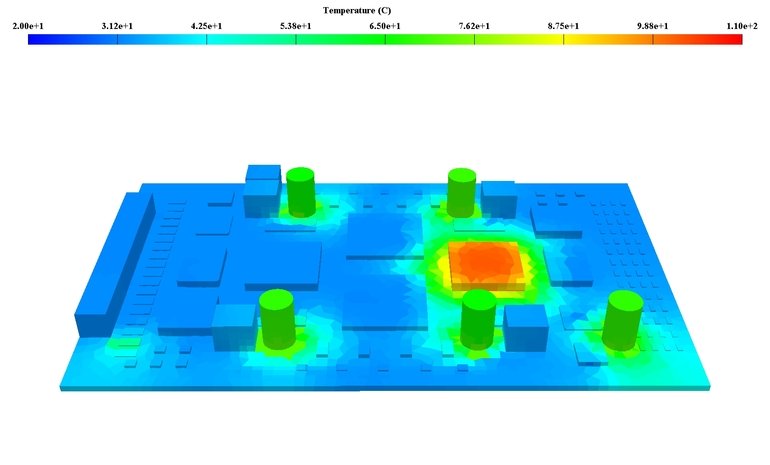

This software uses a Physics of Failure approach to indicate when thermal temperatures are too hot for integrated circuits and solder joints. The Thermal-Mechanical capability that is now available in the version 5.3 enables users to quickly and easily run thermal-mechanical analyses directly in Sherlock, saving valuable engineering resources by eliminating time-consuming data-entry. By using the analysis, it provides more accurate thermal profiles of product designs, especially early on in product development where they can have the most impact.

This also enables design improvement by changing component type, material parameters, and or layout to minimize loads during thermal expansion. Understanding the interaction of mounting points and components during thermal expansion assures a more reliable PCB layout under thermal-mechanical stresses.

Other features include:

- Increased Parts Library customizability for more efficient parts review

- Revised QFN solder fatigue model – incorporates the effect of mold compound CTE and glass transition temperature on fatigue life predictions

- Help feature – searches through all of Sherlock’s user guides and educational materials

- User tab – traceability for parts creation and modification

- Expanded part library capabilities – permits more flexibility during the export process

- Semiconductor Wearout analysis – incorporates part temperature rises

- GUI changes – improves the overall user-friendliness