Mirtec will premier its complete line of 3D AOI and SPI inspection systems in Booth #3101 at the 2017 IPC APEX Expo. The premier technical conference and exhibition for the electronics manufacturing industry will take place Feb. 14–16, 2017 at the San Diego Convention Center.

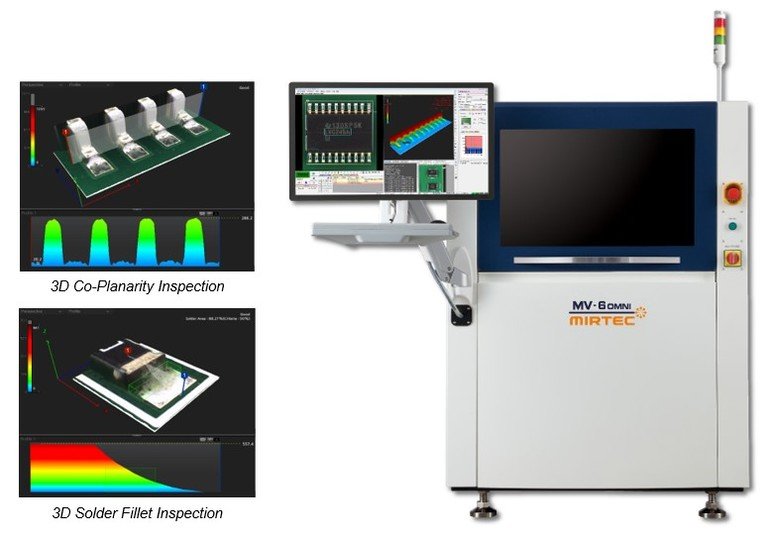

The award-winning MV-6 Omni 3D AOI machine is configured with the exclusive Omni-Vision 3D Inspection technology which combines the 15 Mega Pixel CoaXPress camera technology with the revolutionary Digital Multi-Frequency Quad Moiré 3D system in a newly designed cost effective platform. The company’s 15 Megapixel CoaXPress Vision System is a proprietary camera system designed and manufactured by the company for use with our complete product range of 3D inspection systems. The Digital Multi-Frequency Quad Moiré technology, provides true 3D inspection using a total of four (4) programmable Digital Moiré Projectors to yield precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MV-6 Omni machines feature four (4) 10 Megapixel side-view cameras in addition to the 15 Megapixel top-down camera. There is little doubt that this new technology has set the standard by which all other inspection equipment is measured. The company will have two (2) MV-6 Omni’s on display one configured with a 10 um lens for high-performance applications and the other with a 15um lens for high-speed applications. The company’s award-winning MS-11E 3D SPI machine is configured with the exclusive 15 MP CoaXPress Vision System, providing enhanced image quality, superior accuracy, and incredibly fast inspection rates.

The machine uses Dual Projection Shadow Free Moiré Phase Shift Imaging technology to inspect solder paste depositions on PCBs post screen print for insufficient solder, excessive solder, shape deformity, shift of Deposition, and bridging. The MS-11e uses the same robust platform as the MV-6 Omni series.

The company will have two (2) MS-11e’s on display one configured with a 10um lens for high-performance applications and the other with a 15um lens for high-speed applications.

The MV-7 Omni-QHD 3D AOI machine features the next generation of the Omni-Vision 3D inspection technology in a high-performance AC Servo Drive platform. This revolutionary technology combines our proprietary 15MP CoaXPress Vision System with the exclusive quantum high definition (2048 x 1536) Digital Multi-Frequency 3D Projection technology to provide unprecedented image quality, accuracy, and repeatability necessary for precision inspection of SMT devices on finished PCB assemblies. This new technology will, undoubtedly, set the standard by which all other 3D inspection equipment will be measured. The MV-7 Omni-QHD machine also features four (4) 10 Megapixel side-view cameras for inspection of regions of interest which are not accessible with the 15 MP top-down camera.

The MV-6E In-Line AOI machine combines our exclusive 10 Megapixel top-down camera with a precision 13.4 um telecentric compound lens and four (4) 10 Megapixel side-view cameras in a newly designed cost effective platform. The MV-6e is also configured with the exclusive Intelli-Scan 3D Laser System, providing superior lifted lead detection for gull wing devices and four-point height measurement capability for co-planarity testing of BGA and CSP devices.

The MV-3L Desktop AOI machine is the industry’s most widely accepted five (5) camera desktop AOI system. This system is configured with one top-down view 10 Megapixel camera with a precision 13.4 um telecentric compound lens and four (4) 10 Megapixel side-view cameras. It also features our exclusive Intelli-Beam 3D Laser System. This advanced technology provides: four-point height measurement capability for co-planarity testing of BGA and CSP devices as well as enhanced solder paste measurement capability.

New at the show, the company will feature an MV-3L Omni 3D Desktop AOI machine. The MV-3L Omni is configured with the exclusive Omni-Vision 3D inspection technology which combines our 15 Megapixel CoaXPress camera technology with the revolutionary Digital Multi-Frequency Quad Moiré 3D system in a newly designed desktop platform. The company’s 15 Megapixel CoaXPress Vision System is a proprietary camera system designed and manufactured by the company for use with our complete product range of 3D inspection systems. The company’s Digital Multi-Frequency Quad Moiré Technology, provides true 3D inspection using a total of four (4) programmable Digital Moiré projectors to yield precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MV-3L Omni machine features four (4) 10 Megapixel side-view cameras in addition to the 15 Megapixel top-down camera.

The company’s total quality management system software, Intellisys also will be on display at the show. This software suite promotes continuous process improvement by allowing manufacturers to track and eliminate defects on inspected assemblies.

Share: