Accurate component count is vital for inventory management and production efficiency. Currently, this is a time consuming, labor intensive process. Most machines require an operator load, and a run through of each individual reel to count the components, to then record it manually. Counting using x-ray technology and intelligent algorithms can take as little as 7 seconds for an entire reel, and can interface directly with inventory management software to transfer the count instantly. Loading a reel on a manual counter can take up more time. The Scienscope AXI 5100c is an automated, fast, accurate component counting machine designed to increase productivity. Not only does it take less time and labor to have a proper component count, but the recording of results is more reliable, since it is more error proof.

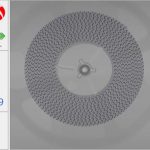

This counting machine uses micro-focus x‐ray technology and a high resolution digital image detector for accurate counting of standard SMT or TH components. A wide range of components, including 01005s and tall components, are supported without having to change hardware thanks to an industrial motion control system that can set the x-ray tube and image detector to various heights and magnifications automatically. Components are counted in the reels and a large database of common component types is included. New types of components are easy to add through a graphic, intuitive interface.

Simple interface/operation

Operation couldn’t be easier – insert the reel and close the door. The machine starts counting automatically. No need to position the reel or set parameters. A built in mapping camera locates the reel and moves the tube and detector to the correct location.

Configuration for batch

The standard machine is an offline system with a table to place the reels, which is accessible through the front door. Once you close the door the machine will automatically start.

Configuration for inline (Hybrid)

If complete automation is the requirement, it can be configured with a wide flat belt conveyor or a rail conveyor to move the reels in and out of the machine automatically. Special carrying trays are supported and Scienscope can also develop the entire handling system to get the reels into the storage tower, or can be directly communicated with various handling systems via industry standard SMEMA interface, or other special protocols. The inline system can also be used in batch mode by accessing the front door.

Accuracy and Repeatability

An inaccurate count is dangerous because other operations rely on the count being correct, which can then results in machine downtime and inaccurate inventory management. The machine count accuracy is 99% for all supported component types. Whether the components are tightly wound or loose on the reel, you can always be sure the count will be correct.

The smaller footprint inline AXC 800 is also available, that is just as reliable, accurate, and also with an easy interface.