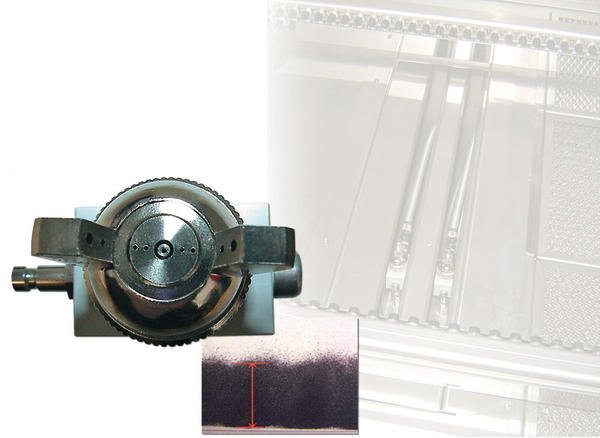

Seho Systems, a worldwide leading manufacturer of soldering systems, completely redesigned the fluxer area of its wave soldering systems. As a result both, the flux consumption as well as maintenance times are reduced remarkably which helps to decrease manufacturing costs in the electronics production. The ATS spray fluxer, developed by the company has several advantages. In this closed system, a rotary pump continuously transports the flux from the flux container into a bypass system. For spraying, a bypass valve interrupts the circuit and leads the flux to the spray head. The new spray head is based on HVLP technology (high volume low pressure) which generates atomization of the flux with a comparatively low pressure. This ensures a stable spray jet with a very homogeneous spray pattern and an extremely good boundary at the outer edges, to enable a remarkable reduction of the flux consumption. Overall this low pressure system creates considerably less spray mist which results in a notable reduction of soiling in the fluxer area. Thus, maintenance requirements are minimized. The flux quantity and spray pressure are adjustable. All connections are designed as quick-acting closures and the spray head is quickly exchangeable. The flux container, which is equipped with an additional cover, can be taken out completely to allow easy cleaning. All electrical and pneumatical parts remain in the soldering system.

The ATS spray fluxer with HVLP technology is available for all wave soldering systems from the company and also may be refitted at older machines.

Share: