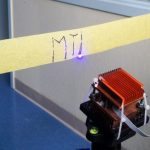

In a ribbon cutting ceremony, Mirrorcle Technologies inaugurated its new cleanroom space at the company’s Richmond, CA headquarters. Reflecting the company’s core competency of reliable optical beam-steering, the ribbon was cut by one of company’s latest products – a laser beam Scan Module which features a powerful 1W, blue (450 nm) laser that was developed for the emerging dynamic solid-state lighting (phosphor lighting) market. As the founder and CEO, Dr. Veljko Milanovic, dragged his finger on a tablet controlling the battery-powered Scan Module via Bluetooth, the laser beam, which was steered by the company’s 1.2 mm diameter A3I12.2–1200AL MEMS mirror, cut open access to the new manufacturing space adjacent to their headquarter.

The event was lightheartedly named “Facility expansion and new cleanroom opening ceremony” or FENCOC 2018. The team, including delegations from its Taiwan and China offices, were joined in its celebration by long-time supporters, vendors, customers, and friends who were welcomed into the newly remodeled, approx. 2000 sq. ft. facility. Dr. Milanovic gave a brief speech on the company’s history. “This is our sixth facility as we have continually grown since those early days near UC Berkeley’s campus.” Dr. Milanovic said – “We continue to expand here at Point Isabel surrounded by the waters of the San Francisco Bay which we enjoy viewing from every window.”

The graph that goes “up”

After showing graphs of production and shipment increases, Dr. Milanovic explained in some more detail the need for expansion of its production specifically for standard serial-production designs: “The opening of our cleanroom facility significantly expands our in-house manufacturing capability and supplements our established in-house, as well as outsourced MEMS mirror production. With this new facility, we can confidently offer an increased number of MEMS designs at higher volumes and it also allows us to continue catering to low-quantity highly customized beam-steering solutions as required by some customers for their special applications. While expanding our standard production “downstairs” we continue to have the flexibility to serve R&D needs “upstairs.”

Opening ceremony full of moving lights

From the foyer of the facility, throughout its hallways, its cleanroom, and even kitchen area, there were laser beams projecting a variety of graphic content and demonstrating some of the company’s products. A tracking system was ready for any visitor to toss the ping pong ball and watch it being chased by the laser light. A 3D scanning system measured objects continuously presented before it in a manner used by some of their 3D metrology customers. Dynamic laser phosphor signs were projected on cleanroom walls in pure white light next to scrolling laser displays. A 720p projector for video-rate imaging and displays projected onto a wall in the “Wafer Room”. The shown demos were a small selection of the variety of different applications in which MEMS mirrors often act as enabling technologies, ranging from displays, 3D metrology and LIDAR over biomedical imaging to free-space optical (FSO) communications.