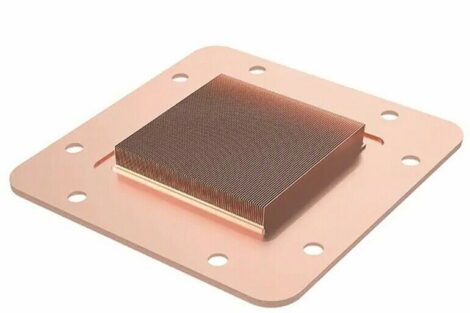

Computers get very hot! Heat sinks need to efficiently conduct heat away from the electronic components that generate this heat. The Tactilus heat-sink analysis system by Sensor Products Inc. enables research and design engineers to quickly and precisely test and correct the surface contact and pressure distribution between the heat sink and its source. Even a slight warping of the heat exchange structure or reduction in surface contact area can have a profound effect on cooling efficacy. If the pressure distribution is not uniform, heat conduction will be low, and the electronics may overheat.

Sensor Products Inc., Madison New Jersey (USA)

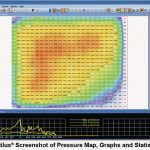

With Tactilus, engineers can visualize actual contact forces and pressure distribution data on the circuit board components. As the mounting screws between the CPU and the heat sink are torqued, maps and measures the changing pressure distribution between the mating surfaces and displays it through its software. The heat sink interface can be tested, manipulated, and repositioned in real-time, speeding the trial and error process and eliminating the need for additional assembly. The system also provides the pressure data needed for FEA simulation predictions.

Unlike conventional transducers, the sensor is flexible and only 0.015-in. thick (0.38 mm), allowing it to be placed between the CPU and heat sink without affecting the assembly. The sensor pad has 625 resistive sensing points arrayed on a 25 × 25 grid. The total sensing area is 2 in. × 2 in. The scan speed is up to 1,000 Hertz, and the operating pressure range is 0 to 100 psi (0 to 7 kg/cm2).

It collects and processes sensor data using powerful, easy-to-use, Windows-based software that performs the following tasks:

- Creates pressure vs. time graphs and histograms

- Performs 2D, 3D and 360 degree image rendering and region of interest scaling

- Displays maximum, minimum, and average pressures and does force integrations and

- Prepares reports through export to Excel, ASCII, or Access formats.

The sensor system will endure hundreds of diagnostic uses on different heat sinks with consistent repeatability. It is highly resistant to electromagnetic noise, temperature, and humidity fluctuations. Accuracy is ±10 %; repeatability is ±2 %; hysteresis is ±5 %; and non-linearity is ±1.5 %. The Tactilus Sensor System is very versatile and can be adapted to virtually any measurement modality or application to see surface pressure distribution in real time. It is used to map and measure surface pressure distribution at the interface of tire tread footprints, door seals, heat seals, fuel cells, printed circuit boards, flat panel displays and wafer polishing, among its many uses.

The company provides off-the-shelf as well as custom design solutions for special applications. In addition, Dynamic Link Library (DLL) files and the Graphical User Interface (GUI) can be tailored to the customer’s request.

Zusammenfassung

Die Architektur des Oberflächensensors Tactilus ist modular, transportfähig und leicht skalierbar bei gleichzeitiger Datenerfassung von bis zu vier getrennten Sensorpads. Es ist ein Werkzeug, bestehend aus einem elektronischen Sensorelement, Elektronik und Software.

L’architecture du capteur de surface Tactilus est modulaire, transportable et facile à cadrer en cas de saisie simultanée de données allant jusqu’à quatre pads séparés. C’est un outil qui se compose d’un élément capteur électronique, d’un système électronique et d’un logiciel.

Share: