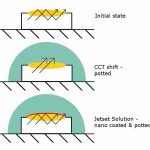

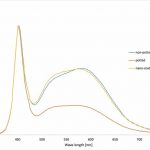

The colour temperature (CCT – Correlated Colour Temperature) of white LEDs is produced by luminescent colourants transforming a portion of the short-wave blue light into long-wave yellow light, which will give a white light. In the potting process, the colour temperature on the interface between the conversion layer/potting interface is displaced, due to physical influence, towards the short-wave blue area and will therefore appear colder. The desired warm portion of the light provoked by its yellow portion will disappear.

Subject to poor/irregular adhesion, this effect may be more or less intense, which will result in different colour temperatures. In order to achieve both a consistent colour temperature and a reliable protection, a homogeneous and good adhesion of the potting is indispensable.

Jetset solution by Lackwerke Peters provides a solution to control the cold-light shift effect: The Elpecast Nano Primer NP 4 LED is applied in a very thin layer on the LEDs, evenly and reproducibly, prior to potting. Once the solvent formulated has completely evaporated, a fine film will be left on the LEDs. Subsequent potting with a crystal-clear Elpecast casting compound will prevent the shifting of the LEDs’ colour temperature and ensure an even result through optimum adhesion.

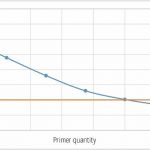

The solution causes repeated passage of the light through the conversion layer, which converts blue light portions into yellow ones. Depending on the quantity of primer applied, one can achieve a precise colour temperature. All depending on the luminescent colourants present in the conversion layer, as well as, on the geometry, the surface, the performance and the initial colour temperature of the LEDs.

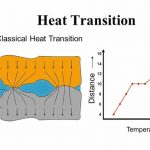

Thermal management of LEDs

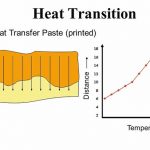

Based on silicone resins, the Elpepcb Thermal Interface Paste, TIP 2792, is applied on the interface between the printed circuit board and the heatsink or heat-dissipating casing. Due to its elasticity, it ensures a reliable thermal connection and improves the heat transfer and heat dissipation while the operating heat is efficiently lowered. Heat vias can be safely filled with this paste in view of enlarging the thermal interface. Applied by screen printing in different structures and layer thicknesses, it is less costly than heat-conductive metal foils, for example, which have to be cut to fit their respective application.

Selective coating and curing is made at the PCB manufacturer’s site prior to soldering, on the bare printed circuit board in the desired layout. This way, the user already receives the printed circuit boards with the TIP. As an alternative, by using the heatsink pastes, one can fully dispense with heat-conductive metal sheets and thus reduce the number and size of thermal transfer resistances. Based on epoxy resins, these are highly heat-conductive, electrically insulating 1-pack screen printing inks which are an alternative to commonly used cooling elements. The heatsink pastes can be directly printed in heat vias and on the metal surfaces of the printed circuit board. Since there is no need for an insulating adhesive layer, the results are similar to those achieved with metal foils.

It is also possible to combine the two thermal interface pastes in applications, where high insulation properties are required. In this case, HSP 2740 is printed in the heat vias and on the surfaces of the printed circuit board first, followed by the printing of TIP 2792 on top, in order to ensure a good connection to the heatsink. This not only increases the PCB’s reliability, but also the lifespan of the individual components.

A thermal management aimed at a higher radiation performance of LEDs and a longer lifespan of assemblies and high power devices can be easily achieved through an efficient reduction of the operational heat by means of the two pastes. This also reduces the electrical power failures and a higher lumen/Watt performance can be reached.

Zusammenfassung Résumé Резюме

Während LEDs für den Verbraucher in der Regel unkompliziert in der Nutzung sind, stehen die Hersteller vor Herausforderungen bei der Produktion: So bringt die Schutzbeschichtung von Lumineszenzkonversions-LEDs eine unerwünschte Verschiebung von der ursprünglichen Farbtemperatur. Ebenso muss die Betriebswärme abgeführt werden, um den Lebenszyklus zu verlängern. Im Artikel wird der Einsatz von Jetset Solution und Wärmeleitpasten behandelt, welche die Produktion bzw. das Management von LEDs hinsichtlich ihrer Farbtemperatur und Wärmeentwicklung vereinfacht.

Alors que les LED sont généralement faciles à utiliser pour le consommateur, les fabricants sont confrontés à des problèmes de production: le revêtement protecteur des LED de conversion de luminescence, par exemple, provoque un décalage indésirable par rapport à la température de couleur d‘origine. De même, la chaleur de fonctionnement doit être dissipée pour prolonger la durée des LED. L‘article traite de l‘utilisation de Jetset Solution et de la graisse thermique, qui simplifie la production et la gestion des LED en termes de température de couleur et de développement de la chaleur.

Для потребителя светодиоды не представляют никакой сложности в использовании, однако производителям часто приходится сталкиваться с серьезными проблемами при производстве: Так, например, защитное покрытие светодиодов с конверсионным люминофором приводит к нежелательному сдвигу изначальной цветовой температуры. При этом необходимо также отводить тепло для продления срока службы. В статье рассматривается использование Jetset Solution и термопаст, упрощающих производство и эксплуатацию светодиодов, а также снижающих влияние таких факторов, как цветовая температура и тепловыделение.