Electrolube, a manufacturer of specialist electro-chemicals for the automotive, electronics, LED and industrial manufacturing industries, will launch a series of innovative new polyurethane and silicone conformal coating products at this year’s SMT Hybrid Packaging exhibition. The company’s senior technical team will be available to advise visitors of suitable conformal coating, encapsulation resin and thermal management solutions.

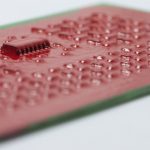

The 2K, two-part conformal coating range has been an important advancement for customers, combining the tough, resistant properties of an encapsulation resin, with the easy application of a coating. The company has extended the range with the new 2K550, 2K850 and 2K750 conformal coatings.

2K550 is a tough, flexible, high performance coating, which has excellent clarity and resistance to discoloration, humidity and condensation. The UL94V-0 compliant polyurethane coating is characterized by greater coating thickness and enhanced edge coverage and shows improved adhesion, hardness and scratch resistance. It also features a fluorescent trace to aid inspection.

The 2K850 two-part, UV cure coating combines the speed and convenience of UV cure with the benefits of the company’s 2K system, merging the properties of a resin with the easy application of a coating. This coating offers a faster processing time while still delivering superb levels of protection. The polyurethane coating is a new product, providing an immediate tack-free coating and enabling complete cure at room temperature within 24 hours, compared to the moisture cure average of 8–14 days. Featuring a wide operating temperature range of –40 to + 130°C, with good thermal shock performance. It also provides a consistent chemical cure and excellent protection against water, moisture, salt mist and condensation, making it ideal for tough electronic applications exposed to harsh conditions.

Due to increasing demand, the company has also developed a silicone 2K conformal coating, 2K750. The UL94V-0 compliant coating provides a wide operating temperature range of – 40 to + 220 °C, with a high continuous use temperature of 200 °C. The tough, low-stress coating has an extremely fast thermal cure time of 10 mins at 80 °C, in addition to curing at ambient temperature, and provides excellent adhesion to most solder resists and metals. The transition to implementing the 2K conformal coatings range couldn’t be simpler with a straightforward valve modification, such as PVA’s VPX-2KS or Nordson Asymtek’s AM range.

Additional new silicone coating products on show include MCS and HCS. The Moisture Cure Silicone (MCS) coating is a soft, flexible, low stress coating with a wide operating temperature range (- 40 to + 200 °C) and a high continuous use temperature of 180 °C. The low viscosity, solvent-free silicone material provides a rapid touch-dry time at ambient conditions (10 mins at 25 °C, 50 % RH), which can be further accelerated with heat, and fully cures within 48 hours.

The new, low-viscosity Heat Cure Silicone (HCS) coating offers an extremely fast full thermal cure time of 10–12 mins at 110 °C. The low odor, solvent-free coating meets the requirements of UL94V-0 and has virtually no cure by-products. Developed with improved adhesion, HCS is a soft, yet tough, low stress coating with a wide operating temperature range (- 40 to + 200 °C) and a high continuous use temperature of 180 °C.

The Managing Director, Ron Jakeman, comments: “Electrolube is increasingly becoming the go-to resource for specialist electro-chemical solutions that solve customers’ manufacturing problems and help them bring high-quality, reliable products to market faster. Our key focus for SMT will be to further endorse our position as a major player in the European market and highlight our expertise as a complete solutions provider in conformal coatings, encapsulation resins and thermal management solutions. We are looking forward to meeting visitors during the event, to learn about their requirements and help advise them on the efficient solutions we offer.”

SMT Hybrid Packaging, Booth 4–548