As a provider of complete solutions in the field of material logistics, Asys has now also put RFID technology on its agenda and presents solutions for various scenarios. From material tracking to setup control – the range of possible applications is enormous.

100 % traceability – know where material is at all times

The company uses RFID technology to seamlessly detect magazines and component reel containers. High-frequency transponders are employed here. This ensures that nearby transponders that are not involved in the process are not read mistakenly. “We chose HF technology to be able to read the RFID tags with NFC functionality, which is now widely used in mobile devices such as smart watches and smart phones. Now material can be traced at different stations, be it at material stations, on AIVs, in the Dry Tower or in the Magazine Warehouse. We can use this data to control and optimize material flows,” says Florian Ritter, Unit Director for Software Solutions & New Business.

Setup in bulk – the intuitive way to replenish

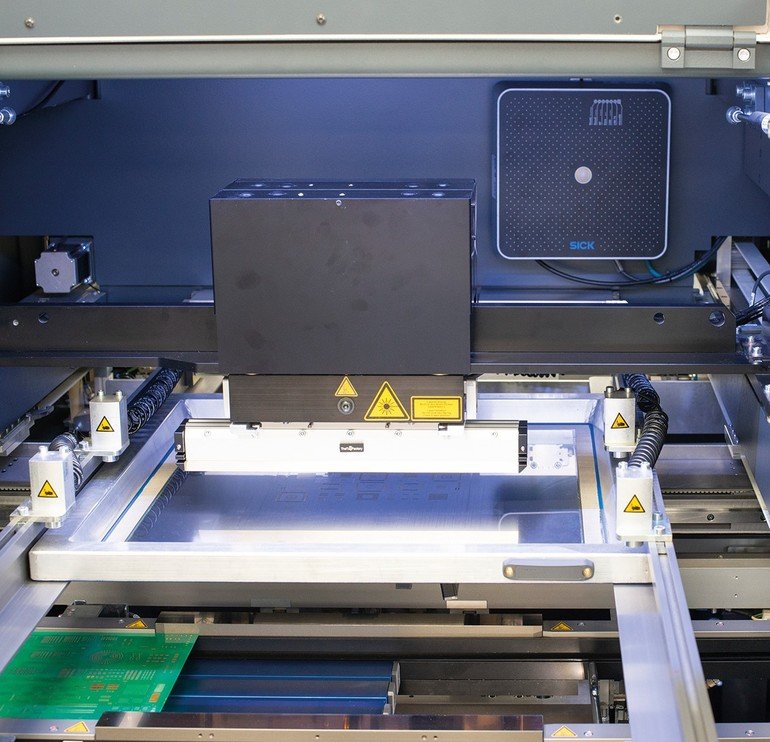

RFID tags in the ultra-high frequency range transmit over greater distances and can therefore be captured in bulk. The company uses the technology for automatic setup control in the printer. “As soon as everything is loaded and its hood closed, the machine checks whether the correct ‘material’ has been set up,” explains Torsten Vegelahn, Unit Director Product Management. The information is displayed on the Simplex HMI. If the setup is incorrect, this describes the next steps to be taken. Bulk scanning does away with the need for time-consuming scanning of the individual material codes. Setup becomes more intuitive and significantly faster.

Triggering simple commands – automate the daily routine on the spot

RFID tags are capable of storing data. This data can be commands that automatically trigger simple actions. Smart products in the consumer sector use this function, for example, to place orders automatically. The company has implemented a scenario with an autonomous transport robot, which can be requested as support. The order process is triggered via a Smart Watch. The new models of Pulse watches with integrated NFC technology make this scenario possible. The Smart Watch just needs to be held up to a tag and a transport robot comes.